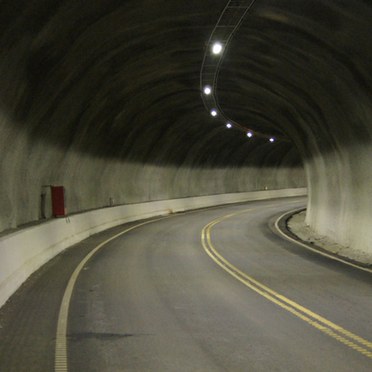

Tinnsjø tunnels, Norway

- Lamp efficacy

Lamp efficacy

Ensuring the lamp efficiently converts electricity into light (lm/W).

- Ballast classification

Ballast classification

Controlling the electricity supply to the lamp (Energy Efficiency Index).

- Luminaire distribution

Luminaire distribution

Controlling light emission using optics which bend and shape the light to the correct location.

- System efficacy

System efficacy

Combining optical and thermal control within the luminaire (luminaire lm/W).

- Presence/absence detection

Presence/absence detection

Providing lighting only when it’s needed.

- Daylight detection

Daylight detection

Reducing waste light during daylight hours.

- Constant illuminance

Constant illuminance

Producing the correct lighting levels for the duration of the maintenance period.

- Task-scene setting

Task-scene setting

Allowing the user to set scenes and adapt the lighting to different tasks.

- Timed off

Timed off

Automatic cut-off to turn all lights off during unoccupied hours.

- Task lighting

Task lighting

Lighting task areas with the correct amount of light.

- Zoning of lighting

Zoning of lighting

Zoning lighting in accordance to occupancy patterns or window location.

- Maintenance schedule

Maintenance schedule

Tailoring maintenance schedules in accordance to product age, performance and environment.

- Waste light

Waste light

Eliminating waste light which does not hit the intended target.

- Reflectance

Reflectance

Taking advantage of light which is reflected from the surface within the space.

- Visible smart metering

Visible smart metering

Enabling results of actions to be quickly seen as increased or decreased energy use to encourage responsible energy consumption.

Two tunnels in Tinnsjo, southern Norway, have been refurbished with Thorn’s GTLED luminaires. In 1992, the tunnels had been fitted with the well-known Gotthard fitting and fluorescent lamp combination. However, with the arrival of more efficient technology offering better quality light, they became Thorn’s first tunnel project in Norway to be completely refurbished and upgraded with LED.

In cooperation with Otera, LED luminaires with a system power of 75W were chosen for the general lighting, with one fitting per 12.85m. In the entrance and transition zones, conventional high pressure sodium lamp fittings with counterbeam optics have been used. Thorn designed the application with a combination of 400W, 150W and 70W high pressure sodium lamps to meet the Norwegian Road Authority’s regulations. This ensures a smooth transition from daylight into the interior zone of the tunnel.

As day turns to night, the lights are dimmed in steps so that high pressure sodium luminaires turn off in groups, and then the LED luminaires are dimmed down to 50 per cent. The LED luminaires are stepless dimmable from 10-100 per cent with a DALI signal, an open digital protocol that functions well with LED technology.

The tunnel is permitted for walking and bicycle traffic, so there are strict requirements for the uniformity of the light. By dimming the light at night, as opposed to turning off every second fitting, the tunnel maintains excellent luminance uniformity. During both night and day the GTLED fittings provide energy savings of approximately 40 per cent compared to conventional 58W fluorescent fittings.

The street lighting outside the tunnels is also provided by Thorn. The Civic fitting with a 250W lamp and automatic 50 per cent dimming between 10pm and 5am were selected for this task. The solution includes a device for each fitting detecting sunrise/sunset and calculates when dimming is to occur based on this data. This requires no external signals and is a solution that is often used on Norwegian roads. If necessary, the dimmable period is easily reprogrammed from the ignition cabinet with an on/off sequence.

Tunnel Project Manager Hans Øien says: “We could see from the calculations that we had a great solution here, but the result really speaks for itself. Achieving this kind of uniformity with such low glare is simply outstanding. It really shows the potential of using cleverly designed LED fittings in tunnels - there is no way we could have done that with this number of fittings and conventional lamp technology. When you also consider the long lifetime of these fittings, the result is reduced maintenance costs, I am sure that a lot of road and tunnel authorities around the world will see this type of solution as a great benefit also.”

Key Facts

- GTLED fittings provide energy savings of approximately 40 per cent compared to conventional 58W fluorescent fittings